SECTION DIAGRAMS

AGITATORS AND MIXERS

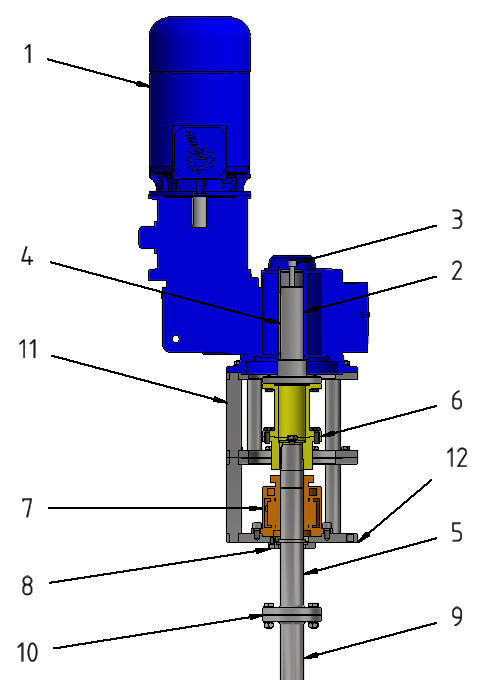

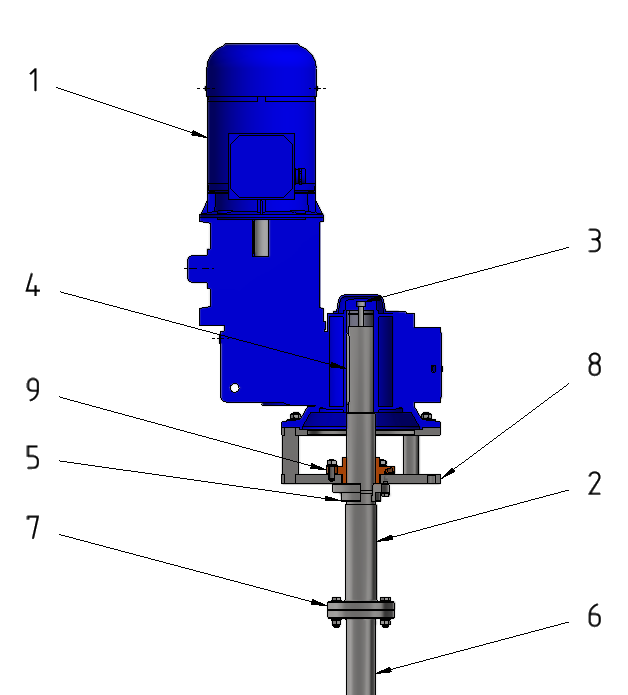

UTS-C(D) Series

Uni Track System agitator (coupling). Agitador with geared motor, double turret, spacer coupling, mixer mechanical seal and flanged or direct shaft (D).

Configuration:

The gearmotor (1) drives the gearbox semi-shaft (2), which is fixed by the axial clamping bolt (3). Power is transmitted through the key (4). The gearbox semi-shaft is connected to the semi-shaft or direct shaft (5) by methods of a spacer coupling (6) that allows access to the mechanical seal (7) without removing the gearmotor. The semi-shaft stopper (8) permits the entire shaft and mixing blade assembly to remain in position while the spacer coupling is removed. In case of incorporating a shaft – semi-shaft assembly (9), these are joined by the semi-shaft coupling (10). The diferent types of turbines available are assembled to the shaft by diferent possible methods (clamp, set screw, welding, etc.).

The assembly rests on the upper flange of the intermediate turret (11) and the agitator is coupled to the tank through the lower flange of the turret (12). The shaft passes through this perimetral structure where, on the lower flange, it is sealed by the action of the mechanical seal. The fastening of the shaft is done by a bearing incorporated in the mechanical seal.

The mechanical seal is of agitation type, balanced and of single or double execution.

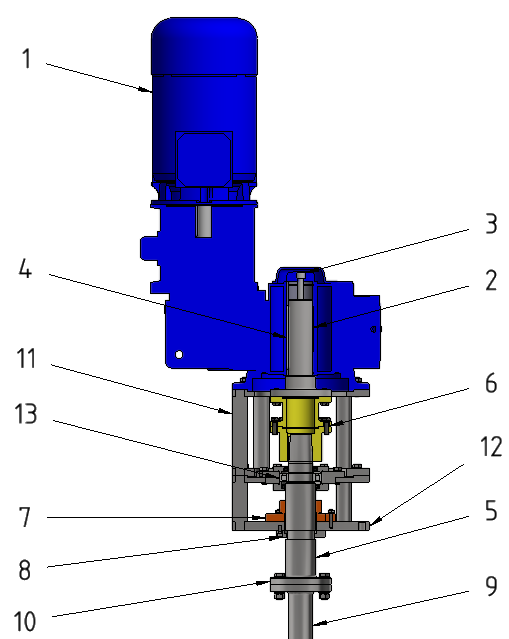

UTS-CR(D) Series

Uni Track System agitator (coupling). Agitador with geared motor, double turret, spacer coupling, mixer mechanical, intermediate bearing seal and flanged or direct shaft (D).

Configuration:

The gearmotor (1) drives the gearbox semi-shaft (2), which is fixed by the axial clamping bolt (3). Power is transmitted through the key (4). The earbox semi-shaft is connected to the semi-shaft or direct shaft (5) by methods of a spacer coupling (6) that allows access to the mechanical seal (7) without removing the gearmotor. The semi-shaft stopper (8) permits the entire shaft and mixing blade assembly to remain in position while the spacer coupling is removed. In case of incorporating a shaft – semi-shaft assembly (9), these are joined by the semi-shaft coupling (10). The diferent types of turbines available are assembled to the shaft by diferent possible methods (clamp, set screw, welding, etc.).

The assembly rests on the upper flange of the intermediate turret (11) and the agitator is coupled to the tank through the lower flange of the turret (12). The shaft passes through this perimetral structure where, on the lower flange, it is sealed by the action of the mechanical seal. The fastening of the shaft is done by a bearing located in the perimetral structure.

The mechanical seal is of agitation type, balanced and of single or double execution.

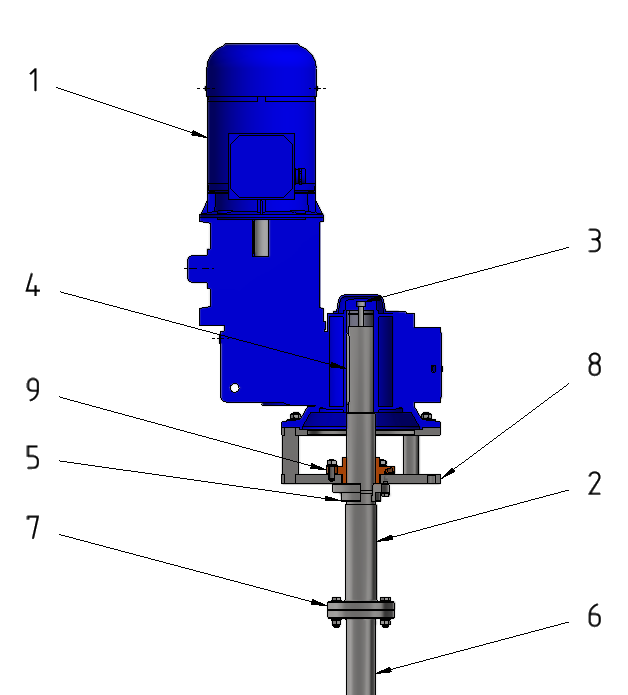

UTS-S(D) Series

Uni Track System agitator (standard). Agitator with geared motor, single turret, without coupling, mixer mechanical seal or cartridge and

flanged or direct shaft (D).

Configuration:

The gearmotor (1) drives the semi-shaft or direct shaft (2), which is fixed by the axial clamping bolt (3). Power is transmitted through the key (4). The semi-shaft stopper (5) allows the entire assembly of the shaft and mixing blade assembly to remain in position while the gearmotor is removed. In the case of incorporating a shaft – semi-shaft assembly (6), these are joined by the semi-shaft coupling (7). The different types of turbines available are assembled to the shaft by different possible methods (clamp, stud, welding, etc.).

The assembly rests on the upper flange of the turret (8) and the agitator is coupled to the tank through its lower flange. The shaft passes through the turret, where it is sealed by the action of a mechanical seal (9).

The mechanical seal incorporated is of agitation type or cartridge type, balanced and of single or double execution

UTS-B(D) Series

Uni Track System agitator (flange). Agitator with geared motor, flange, without coupling, single seal or lip seal and

flanged or direct shaft (D).

Configuration:

The gearmotor (1) drives thesemi-shaft or direct shaft (2), which is fixed by the axial clamping bolt (3). Power is transmitted through the key (4). In the case of incorporating a shaft – semi-shaft assembly (5), these are joined by the semi-shaft coupling (6). The different types of turbines available are assembled to the shaft by different possible methods (clamp, stud, welding, etc.).

The assembly rests on the agitator flange (7), and it is coupled to the tank by methods of it. The shaft passes through the flange, where it is sealed by the action of a lip seal (8).

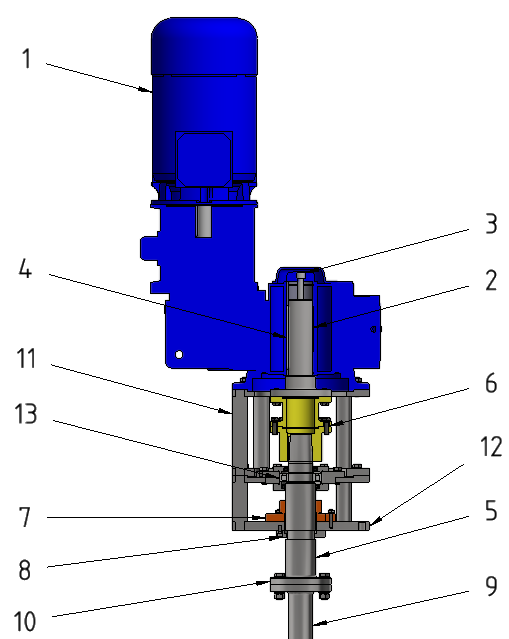

UTS-C (R) (D) Series

Uni Track System agitator (coupling). Agitator with geared motor, double turret, spacer coupling, stirring seal, intermediate bearing (R) and flanged or direct shaft (D).

Setting:

The gearmotor (1) drives the semi-shaft of the reducer (2), which is fixed by the axial clamping bolt (3). Power is transmitted through the key (4). The semi-shaft of the reducer is connected to the semi-shaft or direct shaft (5) by means of a spacer coupling (6) that allows access to the mechanical seal (7) without removing the gearmotor. The semi-shaft stopper (8) allows the entire shaft and stirrer blade assembly to remain in position while the spacer coupling is removed. In case of incorporating a shaft-semi-shaft assembly (9), these are joined thanks to the coupling of the semi-shaft (10). The different types of turbines available are attached to the shaft by different possible means (clamp, stud, welding, etc.).

The assembly rests on the upper flange of the intermediate turret (11) and the agitator is coupled to the tank through the lower flange of the turret (12). The shaft passes through this perimeter structure where, on the lower flange, it is sealed by the action of the mechanical seal.

The built-in mechanical seal is of the agitation type, balanced and single or double execution.

UTS-S(D) Series

Uni Track System shaker (standard). Agitator with geared motor, simple turret, without coupling, stirring seal or cartridge and

flanged or direct shaft (D).

Setting:

The gearmotor (1) drives the direct shaft or semi-shaft (2), which is fixed by the axial clamping bolt (3). Power is transmitted through the key (4). The semi-shaft stop (5) allows the entire assembly of the shaft and stirrer blades to remain in position while the gearmotor is removed. In the case of incorporating a shaft-semi-shaft assembly (6), these are joined thanks to the coupling of the semi-shaft (7). The different types of turbines available are attached to the shaft by different possible means (clamp, stud, welding, etc.).

The assembly rests on the upper flange of the turret (8) and the agitator is coupled to the tank through its lower flange. The shaft passes through the turret, where it is sealed by the action of a mechanical seal (9).

The mechanical seal incorporated is of agitation type or cartridge type, balanced, single or double execution.

UTS-B(D) Series

Uni Track System agitator (flange). Agitator with geared motor, flange, without coupling, single seal or retainer and

flanged or direct shaft (D).

Setting:

The gearmotor (1) drives the direct shaft or semi-shaft (2), which is fixed by the axial clamping bolt (3). Power is transmitted through the key (4). In the case of incorporating a shaft-semi-shaft assembly (5), these are joined thanks to the coupling of the semi-shaft (6). The different types of turbines available are attached to the shaft by different possible means (clamp, stud, welding, etc.).

The assembly rests on the stirrer flange (7), and it is coupled to the tank by means of it. The shaft passes through the flange, where it is sealed by the action of a lip seal (8).