HOMOGENIZERS

HOMOGENIZERS

The industrial homogenisers SEVEN M.X.O.N. work by shear, percussion and ultrasonic frequency shocks.

The intense turbulence they develop inside their micronising chambers allows for better dispersions, emulsions, homogenisations, etc.

These are some of the possible applications:

- Pharmaceutical industry

- Production of stable suspensions

- Production of syrups

- Homogenisation of active substances in ointments

- Production of cosmetics

- Production of masses for lipsticks, nail polish and soap creams

- Production of gazpacho and salmorejo

- Participation in chemical processes (acceleration of reactions)

- Production of fertilisers (both liquid and gel).

The industrial homogenisers SEVEN M.X.O.N. are designed for bottom tank inlet, while the models of the SEVEN M.X.O.N.-M and M.X.O.N.-H series are of horizontal construction on a base plate. Due to their pumping capacity, they can work both in continuous and recirculation mode, thus allowing a wide range of process operations such as addition, in-line homogenisation, recirculation homogenisation, transfer to the next point, cleaning processes, etc. They are generally used with low speed agitators (or FULLVISC type) for high viscosity products.

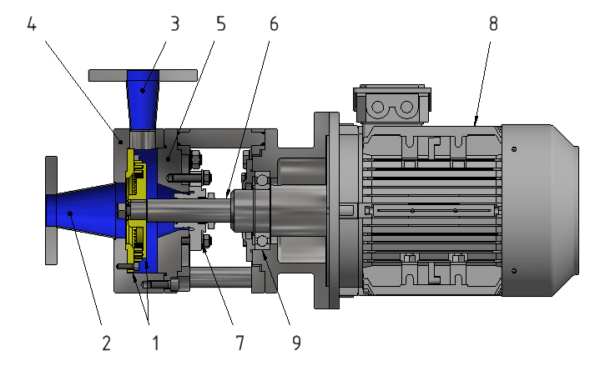

| MXON-M configuration: The high-speed rotation of the rotor within the precisely adjusted stator (1) generates a powerful suction, directing the mixture from the suction (2) towards the impulse (3). Inside, the centrifugal force directs the fluid towards the periphery of the body (4), where it is forced to pass through very narrow interstices at high speed. The intense shearing, percussion and ultrasound guarantee the best dispersions, homogenizations and emulsions at the exit of the machine, thus maintaining a mixing and pumping cycle. From the rear, the casing (5) closes the hydraulic cavity of the machine, allowing the passage of the shaft (6) and housing the mechanical seal (7). The shaft mates with the motor shaft (8) and in some sizes includes a third support bearing (9). The standard mechanical seal type is single or double execution balanced cartridge type. |

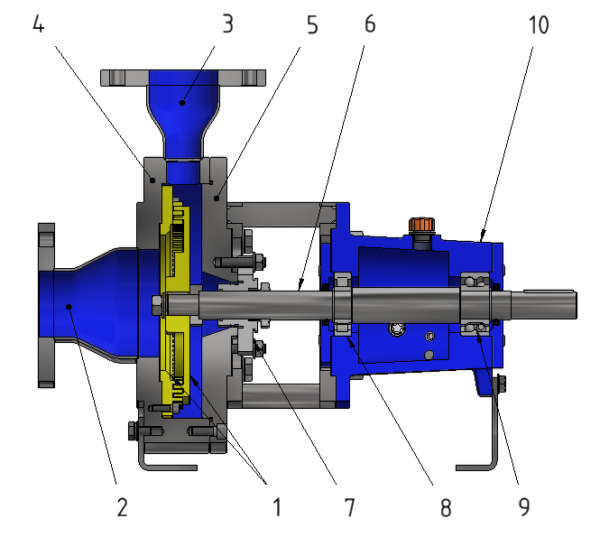

MXON-H configuration: The high-speed rotation of the rotor within the precisely adjusted stator (1) generates a powerful suction, directing the mixture from the suction (2) towards the impulse (3). Inside, the centrifugal force directs the fluid towards the periphery of the body (4), where it is forced to pass through very narrow interstices at high speed. The intense shearing, percussion and ultrasound guarantee the best dispersions, homogenizations and emulsions at the exit of the machine, thus maintaining a mixing and pumping cycle. From the rear, the casing (5) closes the hydraulic cavity of the machine, allowing the passage of the shaft (6) and housing the mechanical seal (7). The shaft is supported by oil-lubricated bearings sealed by seals (8, 9), mounted on a bearing support (10). The fixing legs are located under the body. The standard mechanical seal type is single or double execution balanced cartridge type. |  |

M.X.O.N. in-line homogenizer

| MODEL | FLOW RATE (máx.) (l/h) | MOTOR POWER (kW) | PERIPHERAL SPEED (m/s) | DIMENSIONS | PARTS LIST | |||

| M.X.O.N.-M 120 | 2000 | 4 | 5,5 | 7,5 | 18 | |||

| M.X.O.N.-M 145 | 5000 | 5,5 | 7,5 | 11 | 22 | |||

| M.X.O.N.-H 195 | 14000 | 11 | 15 | 18,5 | 29 | |||

| M.X.O.N.-H 245 | 32000 | 22 | 30 | 37 | 37 | |||

M.X.O.N. bottom vertical homogenizer

| MODEL | FLOW RATE (máx.) (l/h) | MOTOR POWER (kW) | PERIPHERAL SPEED (m/s) | DIMENSIONS | PARTS LIST | |||

| M.X.O.N. 120 | 2000 | 4 | 5,5 | 7,5 | 18 | |||

| M.X.O.N. 145 | 5000 | 5,5 | 7,5 | 11 | 22 | |||

| M.X.O.N. 195 | 14000 | 11 | 15 | 18,5 | 29 | |||

| M.X.O.N. 245 | 32000 | 22 | 30 | 37 | 37 | |||

DOCUMENTATION

- Instruction book