AGITATORS AND MIXERS

For SEVEN an agitator is not simply mechanical equipment. It is also, and mainly, a part of the process. So we enter “agitation engineering”, which consists of studying the appropriate physico-chemical conditions for each process.

An agitator can thus be the main part of a process. Designing to prevent potential breakdowns can avoid significant financial loss by stopping a manufacturing cycle.

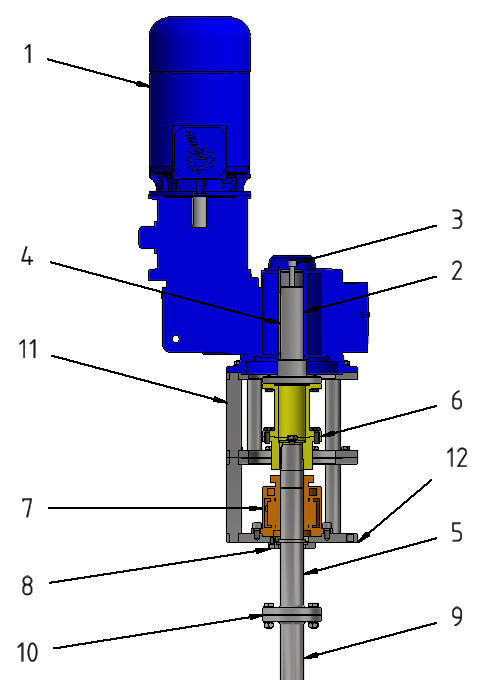

| Serie UTS-C(D)Uni Track System agitator (coupling). Agitador with geared motor, double turret, spacer coupling, mixer mechanical seal and flanged or direct shaft (D). Configuration: The gearmotor (1) drives the gearbox semi-shaft (2), which is fixed by the axial clamping bolt (3). Power is transmitted through the key (4). The gearbox semi-shaft is connected to the semi-shaft or direct shaft (5) by methods of a spacer coupling (6) that allows access to the mechanical seal (7) without removing the gearmotor. The semi-shaft stopper (8) permits the entire shaft and mixing blade assembly to remain in position while the spacer coupling is removed. In case of incorporating a shaft – semi-shaft assembly (9), these are joined by the semi-shaft coupling (10). The diferent types of turbines available are assembled to the shaft by diferent possible methods (clamp, set screw, welding, etc.). The assembly rests on the upper flange of the intermediate turret (11) and the agitator is coupled to the tank through the lower flange of the turret (12). The shaft passes through this perimetral structure where, on the lower flange, it is sealed by the action of the mechanical seal. The fastening of the shaft is done by a bearing incorporated in the mechanical seal. The mechanical seal is of agitation type, balanced and of single or double execution. |

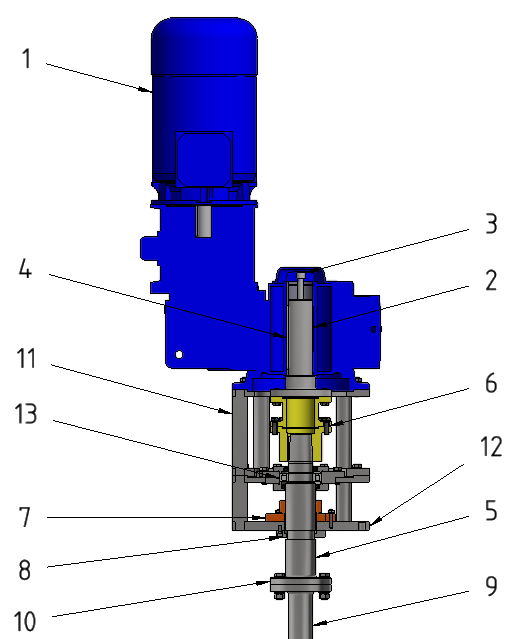

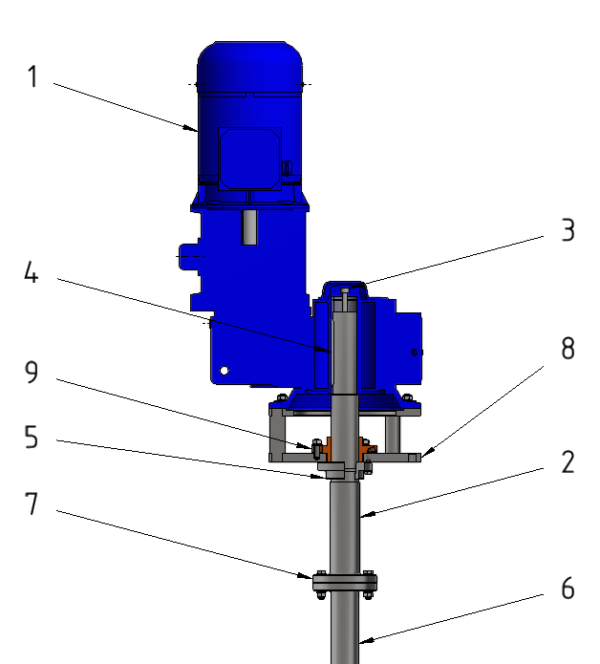

Serie UTS-CR(D)Uni Track System agitator (coupling). Agitador with geared motor, double turret, spacer coupling, mixer mechanical, intermediate bearing seal and flanged or direct shaft (D). Configuration: The gearmotor (1) drives the gearbox semi-shaft (2), which is fixed by the axial clamping bolt (3). Power is transmitted through the key (4). The earbox semi-shaft is connected to the semi-shaft or direct shaft (5) by methods of a spacer coupling (6) that allows access to the mechanical seal (7) without removing the gearmotor. The semi-shaft stopper (8) permits the entire shaft and mixing blade assembly to remain in position while the spacer coupling is removed. In case of incorporating a shaft – semi-shaft assembly (9), these are joined by the semi-shaft coupling (10). The diferent types of turbines available are assembled to the shaft by diferent possible methods (clamp, set screw, welding, etc.). The assembly rests on the upper flange of the intermediate turret (11) and the agitator is coupled to the tank through the lower flange of the turret (12). The shaft passes through this perimetral structure where, on the lower flange, it is sealed by the action of the mechanical seal. The fastening of the shaft is done by a bearing located in the perimetral structure. The mechanical seal is of agitation type, balanced and of single or double execution. |  |

| Serie UTS-S(D)Uni Track System agitator (standard). Agitator with geared motor, single turret, without coupling, mixer mechanical seal or cartridge and Configuration: The gearmotor (1) drives the semi-shaft or direct shaft (2), which is fixed by the axial clamping bolt (3). Power is transmitted through the key (4). The semi-shaft stopper (5) allows the entire assembly of the shaft and mixing blade assembly to remain in position while the gearmotor is removed. In the case of incorporating a shaft – semi-shaft assembly (6), these are joined by the semi-shaft coupling (7). The different types of turbines available are assembled to the shaft by different possible methods (clamp, stud, welding, etc.). The assembly rests on the upper flange of the turret (8) and the agitator is coupled to the tank through its lower flange. The shaft passes through the turret, where it is sealed by the action of a mechanical seal (9). The mechanical seal incorporated is of agitation type or cartridge type, balanced and of single or double execution |

Serie UTS-B(D)Uni Track System agitator (flange). Agitator with geared motor, flange, without coupling, single seal or lip seal and Configuration: The gearmotor (1) drives thesemi-shaft or direct shaft (2), which is fixed by the axial clamping bolt (3). Power is transmitted through the key (4). In the case of incorporating a shaft – semi-shaft assembly (5), these are joined by the semi-shaft coupling (6). The different types of turbines available are assembled to the shaft by different possible methods (clamp, stud, welding, etc.). The assembly rests on the agitator flange (7), and it is coupled to the tank by methods of it. The shaft passes through the flange, where it is sealed by the action of a lip seal (8). |  |

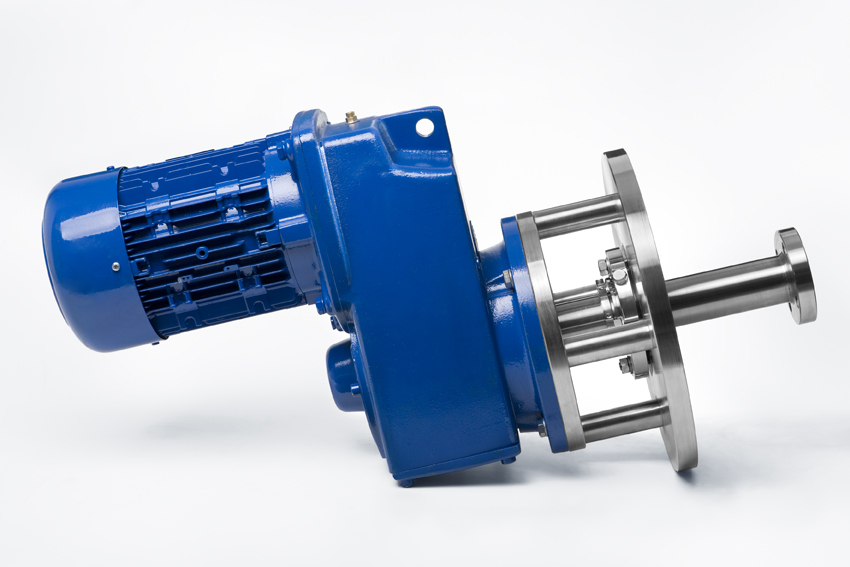

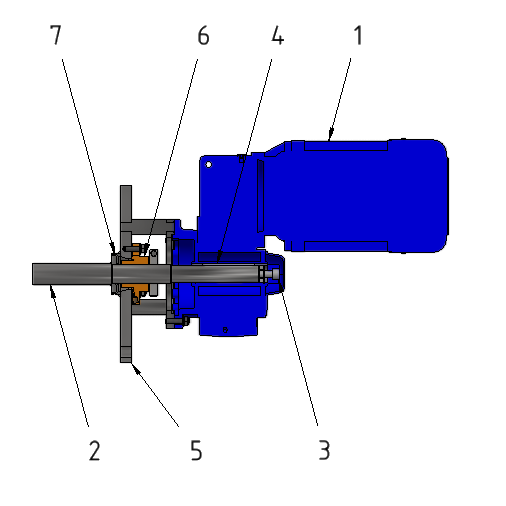

| UTS-L SeriesUni Track System agitator (side entry). Side entry agitator with gearmotor, simple turret, mixing mechanical seal or cartridge, direct shaft and no tank emptying dismantling system. Configuration: The gearmotor (1) drives the direct shaft (2), which is fixed by the axial clamping bolt (3). The power is transmitted thanks to the key (4). The equipment is attached to the tank flange using the turret (5). The shaft passes through the turret, where it is sealed by the action of a mechanical seal (6). The different types of turbines available are attached to the shaft by different possible means (clamp, stud, welding, etc.). The sealing cone (7) incorporates a static seal that remains spaced during normal operation of the equipment. After a few simple steps, the seal is pressed inside the cone, allowing maintenance tasks to be carried out on the seal or the gearmotor without having to empty the tank. The built-in mechanical seal is of agitation type or cartridge type, balanced, single or double execution. |

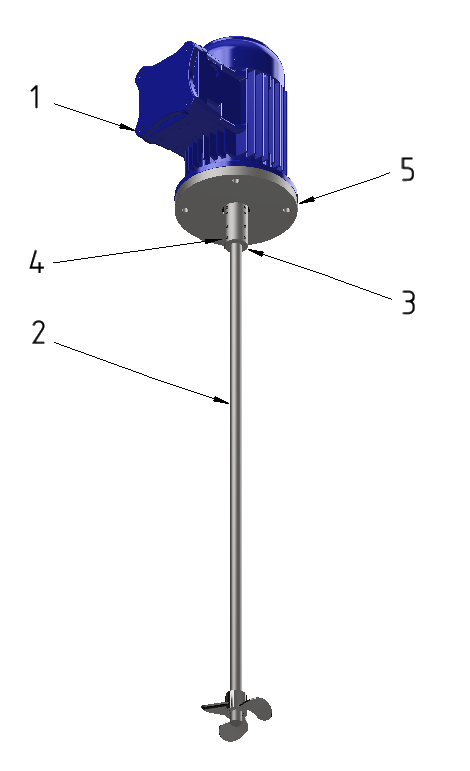

LC SeriesDirect motor agitator. Configuration: The motor (1) drives the shaft (2), which is fixed by the coupling (3). Power is transmitted through the set screws (4). The different types of turbines available are assembled to the shaft by set screws. The assembly rests on the agitator flange (5), and it is coupled to the tank by means of the same. The shaft passes through the flange, where it is sealed by the action of a lip seal (6). |  |

FULLFLOATER-S | Turbulent Axial Flow

· Medium to large size agitations.

· The two-bladed design facilitates its assembly through the manhole.

· Improved flow / power ratio.

· Optimized operation with baffles

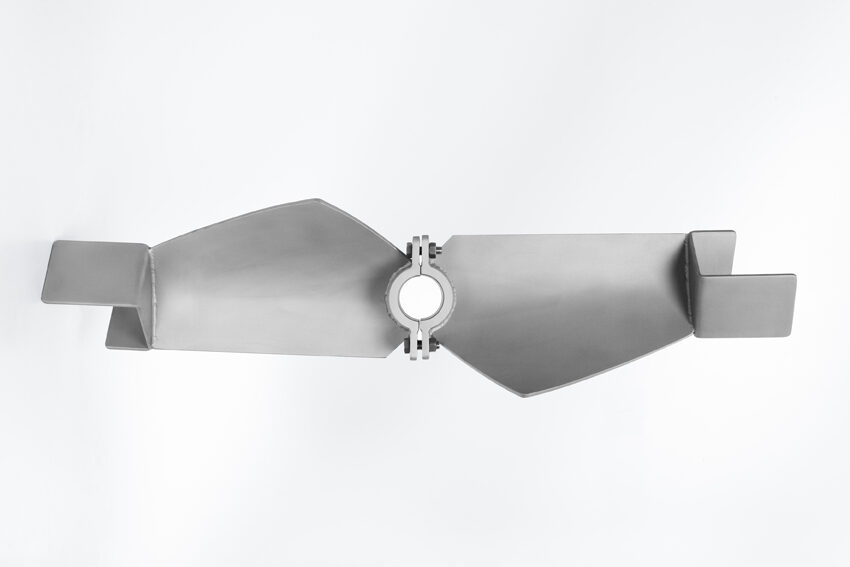

FULLFLOATER-EVO1 | Laminar/Turbulent Axial Flow

· Homogeneous axial flow.

· The two-bladed design facilitates its assembly through the manhole.

· It can operate without baffles

FULLVISC | Positive Laminar Displacement

· Heat transmission processes and / or participation in homogenisations.

· Generation of circulating flow due to fluid displacement.

· Customizable dimensions and aspect ratio.

· May include wall scrapers.

ÁNCORA | Laminar Tangential Flow

· Mixing of viscous products with thermal exchange on the tank walls.

· May include wall scrapers.

COWLES | Dispersion Turbine

· Solid-liquid dispersion and homogenization processes.

VORTEX | Mixture in Viscous Phase

· Solid-liquid mixture in viscous phase.

· Low weight that allows a high speed range.

HÉLICE-F | Complementary Flow

· Geometric adaptation to the bottom of the tank.

· To be mounted together with FULLFLOATER turbines.

· It improves the suspension of particles, directs the flow at the bottom and optimizes the discharge processes.

DOCUMENTATION

- Instruction book