MAGNETIC COUPLING

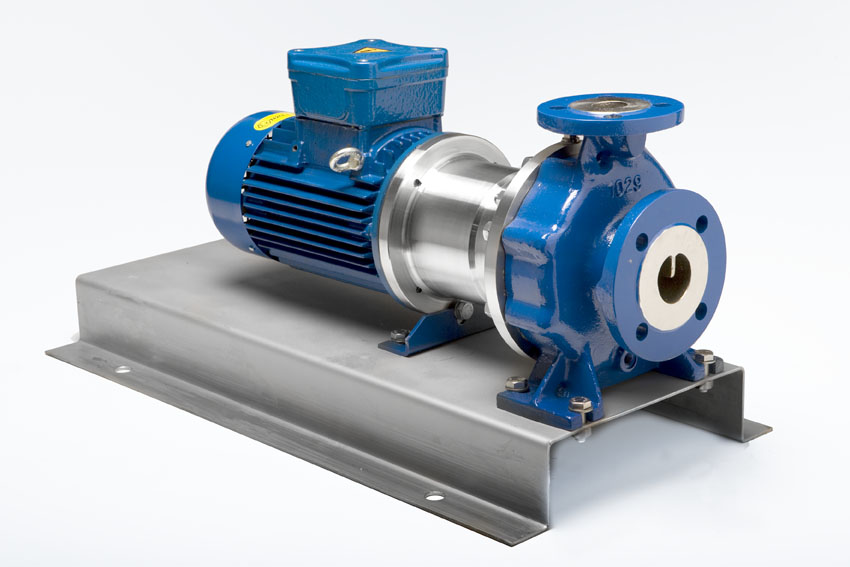

INDUSTRIAL CENTRIFUGAL PUMPS

The magnetic coupling centrifugal pumps SEVEN B.P.Q.M.G. are a derivative of the centrifugal process pump SEVEN B.P.Q. that, with the use of magnets to drive the impeller, make not necessary any contact with the motor shaft.

The magnetic coupling centrifugal pumps are Pumps with low maintenance required, exempt of alignment between the pump itself and the motor and with zero risk of leakage. This makes them essential on the pumping of hazardous or malodorous fluids.

The equality of exterior dimensions of the pump allows a quick conversion to adapt the magnetic coupling, replacing the standard execution and using the same casing and impeller.

The high degree of perfection in its internal design and the very high quality of its materials make it a technological plus today.

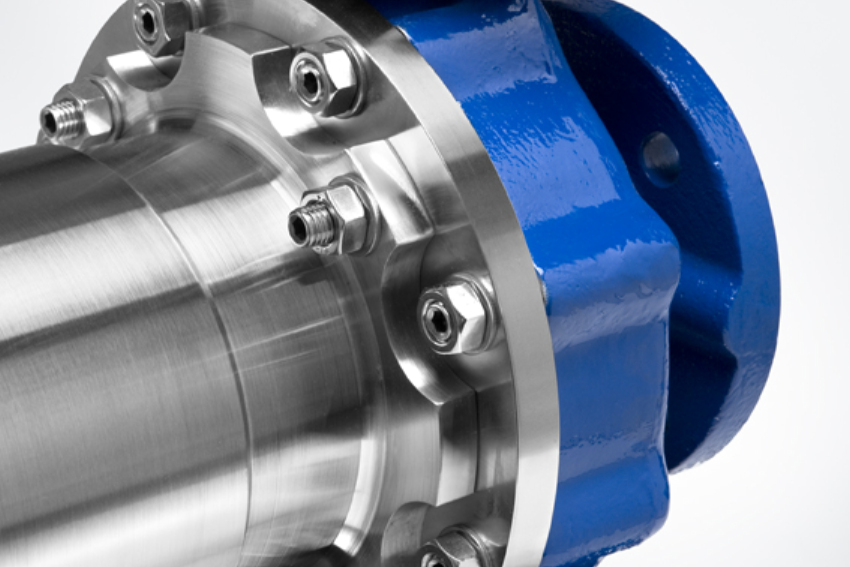

| The pumped liquid enters through the suction pipe (1) axially and due to the impeller (2), the fluid exits by acceleration towards the impulsion pipe (3). The energy generated by the speed of fluid entering and leaving, is transformed into pressure. The axial thrust is balanced by means of discharge blades at the rear side of the impeller (4). As it is a magnetic drive pump, the seal is exclusively due to static seals: a flat seal (5) between the volute (6) and the casing (7) and an O-ring (8) between the casing and the coupling container (9). In this way, the motor (10) transmits the torque to the shaft (11) through the magnetic coupling. The drive is produced by magnetic coupling. The pump is driven by a standard electric motor with a rotation speed of 1500 or 2900 rpm at 50 Hz. Magnetic couplings work without slipping, therefore the motor and the pump rotate at the same speed. The outer rotor (12) receives the torque from the motor and transmits it to the inner rotor (13) through the action of the magnetic field. The internal rotor is part of the rotating unit of the pump, which is supported by bearings lubricated by the pumping fluid itself. These bearings (14, 15) are made of Silicon Carbide resistant to wear and chemical attack. The lubrication circuit begins in the high pressure zone of the volute and leads the fluid towards the inner rotor zone. The fluid passes through the bearing area and is returned to the volute in the low pressure area. This system not only lubricates the bearings, it also dissipates the heat that the assembly receives due to the eddy currents generated by the magnetic coupling. |