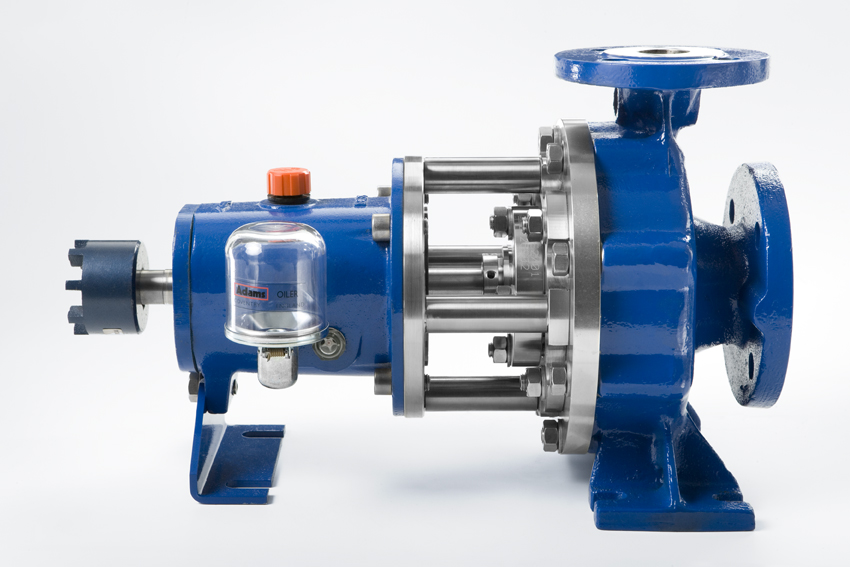

CHEMICAL PROCESS PUMP

INDUSTRIAL CENTRIFUGAL PUMPS

SEVEN centrifugal pumps are known in the industry for their solid construction and smooth operation, as well as being very easy to maintain.

In its design, its industrial application has been taken into account where high performance and low and easy maintenance are essential factors.

This series of pumps conforms to the requirements of EN 22858 / ISO 2858 / ISO 5199 standards, complies with CE regulations and has ATEX certificate.

| The pumped liquid enters through the suction pipe (1) axially and due to the impeller (2), the fluid exits by acceleration towards the impulsion pipe (3). The energy generated by the speed of fluid entering and leaving, is transformed into pressure. The axial thrust is balanced by means of discharge blades at the rear side of the impeller (4). In this hydraulic system the impeller allows the passage of the pump shaft (5) through a protective casing (6) and is sealed by the action of a mechanical seal (7) that seals and prevents possible fluid leaks. The standard mechanical seal type is single or double execution balanced cartridge type. The shaft is supported by oil-lubricated bearings sealed by seals (8, 9), mounted on a bearing support (10). The fixing feet are located under the body. |

DOCUMENTATION

CONTACT