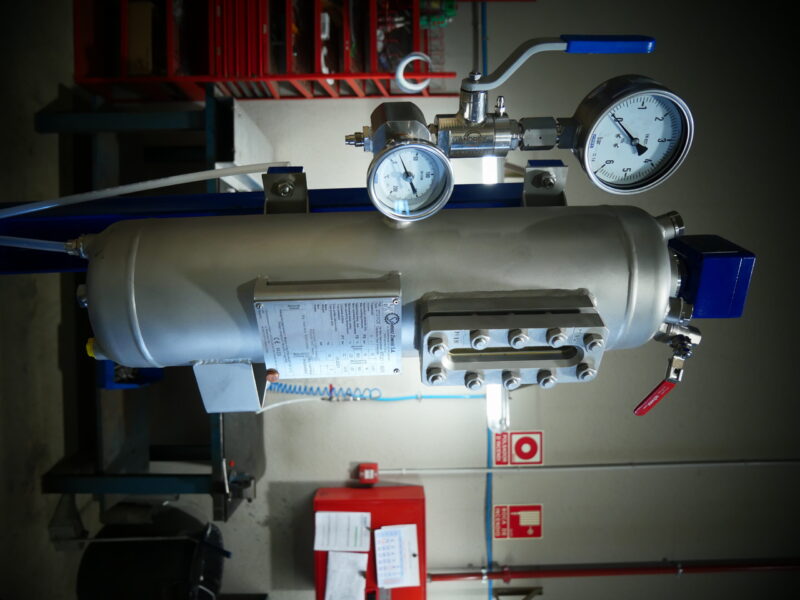

Compared to a conventional mechanical seal, it eliminates the need for manual adjustments and does not require sleeved shafts. In a cartridge, the external mounting of its components makes it possible to isolate the springs from the pumped fluid. The balancing of their sealing faces allows pressures of up to 16 bar without causing wear. With the application of an external thermosyphon and pressurised barrier fluid, the circulation is forced and maintained by an internal pumping ring and by the thermosyphon effect. The pressure of the barrier liquid in the mechanical seal is higher than the process pressure, preventing the pumped liquid from damaging the inner faces of the seal. An internal coil in the thermosyphon is responsible for temperature control.

This system will provide a leak-free and low-maintenance operation, and will ensure compliance with anti-pollution regulations.